Why Carbon Raiser is Essential for High Quality Steel Production

Carbon is the soul of steel. From its hardness to its ductility, carbon determines the fundamental characteristics of every steel grade. In modern steelmaking and foundry production, carbon raiser has become an indispensable additive — not only for restoring carbon content but also for improving metallurgical performance and cost efficiency.

Understanding the Role of Carbon in Steelmaking

Carbon is the key element that defines the structure and properties of steel. During the melting process, especially in electric arc furnaces or induction furnaces, a portion of carbon is lost due to oxidation. This reduction in carbon content can negatively affect the steel’s strength, toughness, and machinability.

To maintain the desired carbon level, manufacturers use carbon raiser (also known as recarburizer) to compensate for this loss. By adding carbon raiser at the right time and in the right proportion, steelmakers can accurately control the carbon percentage in molten steel or iron, ensuring a stable and high-quality final product.

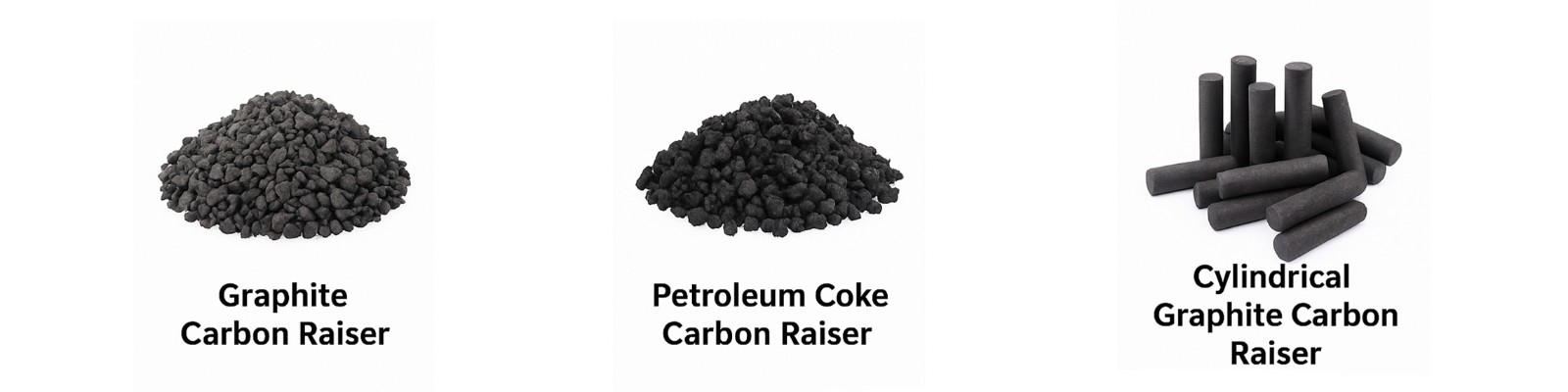

Types of Carbon Raisers

1. Graphite Carbon Raiser

Graphite carbon raiser is the most popular type due to its high fixed carbon content, low sulfur, and excellent absorption efficiency. It melts easily into the molten metal and provides fast and complete carbon recovery.

2. Petroleum Coke Carbon Raiser

Made from calcined petroleum coke, this type offers a cost-effective option with good performance. It is suitable for both foundries and steel plants seeking reliable carbon sources.

3. Cylindrical and Graphite Particle Carbon Raiser

These products have uniform shapes and dense structures, which allow them to dissolve evenly in molten metal. As a result, they provide higher carbon absorption rates and more stable metallurgical results.

Benefits of Using High-Quality Carbon Raiser

1. Improves Carbon Recovery Efficiency

High-quality carbon raiser ensures better carbon dissolution and minimizes carbon loss, leading to higher furnace efficiency.

2. Enhances Mechanical Properties of Steel

With precise carbon control, steel exhibits improved strength, hardness, and wear resistance — all critical factors in industrial and construction applications.

3. Reduces Production Costs

Better absorption means less material is wasted. This reduces overall consumption, decreases slag formation, and optimizes energy use during melting.

4. Ensures Stable and Consistent Quality

Stable carbon input results in predictable metallurgical reactions, helping manufacturers maintain consistent product quality and reduce rejection rates.

Hongshun — Reliable Supplier of Premium Carbon Raisers

As a professional carbon raiser manufacturer, Hongshun provides a comprehensive range of products including:

·Cylindrical graphite carbon raiser

·Graphite particle carbon raiser

·Graphite powder carbon raiser

·Petroleum coke carbon raiser

Our carbon raisers feature high fixed carbon, low sulfur, low ash, and customizable granularity to fit different production requirements. With factory direct sales and strict quality inspection systems, Hongshun ensures competitive pricing and consistent performance for every customer.

In the demanding world of steel production, carbon raiser is far more than an additive — it is a critical factor that determines quality, efficiency, and competitiveness. Whether for refining carbon content, improving furnace efficiency, or producing cleaner and stronger steel, a high-quality carbon raiser is essential.

Choose Hongshun — choose stability, precision, and excellence in every batch of steel you produce.