Silicon carbide, also known as emery or refractory sand, is a widely used inorganic compound with the chemical formula SiC. Industrially, silicon carbide is produced in two main types: black silicon carbide and green silicon carbide.

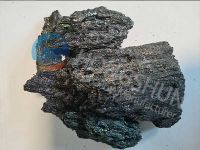

Black Silicon Carbide

Black silicon carbide is manufactured through the reduction reaction of quartz sand and coke powder at high temperatures. It has a Mohs hardness of 9.2 to 9.5 and a microhardness of approximately 3300 kg/cm².

Material Characteristics:

The SiC content in black silicon carbide exceeds 95%. It has greater strength and toughness than green silicon carbide but slightly lower hardness. It is primarily used to process materials with low tensile strength such as cast iron, non-metallic materials, glass, ceramics, stone, refractory materials, and non-ferrous metals.

Material Advantages:

Black silicon carbide's hardness falls between corundum and diamond. It boasts high mechanical strength, stable chemical properties, high thermal conductivity, low thermal expansion coefficient, excellent wear resistance, and possesses certain electrical and thermal conductivity properties.

Green Silicon Carbide

Green silicon carbide is produced by reacting quartz sand, petroleum coke, and sodium chloride at temperatures above 2000°C. It appears as a green, translucent crystal.

Material Characteristics:

The microhardness ranges from 3280 to 3400 kg/cm². It is mainly used for grinding hard gold-containing tools and is suitable for consolidation and coating of abrasive tools, free grinding, and polishing. It is effective for processing materials such as cast iron, cemented carbide, titanium alloys, and high-speed steel.

Material Advantages:

Green silicon carbide features high purity, high hardness, a low expansion coefficient, brittleness, and good thermal conductivity.

Silicon carbide composition

| Brand | Component% | |||

| SiC | F.C | Fe2O3 | ||

| 60# | 60 min | 15-20 | 8-12 | 3.5 max |

| 65# | 65 min | 15-20 | 8-12 | 3.5 max |

| 70# | 70 min | 12-15 | 8-12 | 3.5 max |

| 75# | 75 min | 12-15 | 8-12 | 3.5 max |

| 80# | 80 min | 5-15 | 3.5 max | |

| 85# | 85 min | 5-15 | 3.5 max | |

| 90# | 90 min | 2-10 | 1.2 max | |

| 95# | 95 min | 0.6 max | 1.2 max | |

| 97# | 97 min | 0.3 max | 1.2 max | |

| 98# | 98 min | 0.3 max | 0.8 max | |

| 98.5# | 98.5 min | 0.2 max | 0.6 max | |

sic composition

Silicon Carbide Production Process

Natural silicon carbide deposits are very limited, so silicon carbide blocks are predominantly produced through industrial manufacturing. The production process uses quartz and petroleum coke as raw materials, which are first ground into an appropriate particle size. The raw materials are then mixed in precise ratios before being loaded into an electric furnace for high-temperature smelting.

To regulate the gas permeability of the charge during smelting, an appropriate amount of wood chips is added. Additionally, a specific quantity of salt is incorporated when producing green silicon carbide to facilitate its formation.

The production is carried out in a specialized silicon carbide electric furnace. The furnace is powered on and heated until the center temperature reaches between 2500°C and 2700°C, while the charge temperature reaches approximately 1450°C. Under these conditions, the raw materials undergo a chemical reaction to form silicon carbide (SiC) and release carbon monoxide (CO).

When the charge temperature exceeds 2600°C, partial decomposition of the already formed SiC occurs. However, the silicon released from decomposition reacts again with carbon present in the charge to regenerate SiC, maintaining the overall production balance.

Quality Silicon Carbide Manufacturer Hongshun

As a professional alloy manufacturer, Hongshun produces silicon carbide primarily used as a deoxidizer in steelmaking. Our silicon carbide helps increase silicon and carbon content while effectively deoxidizing molten steel. It features a high specific gravity, allowing easy penetration into molten steel. The material itself offers advantages such as low dust generation, low phosphorus, and low sulfur content. Located in a raw material-rich area, Hongshun benefits from an absolute price advantage in silicon carbide, making our products highly favored by major steel companies.

Hongshun boasts advanced silicon carbide production technology and technical equipment, with a large annual output capacity. We manufacture a variety of silicon carbide products, including silicon carbide blocks, micro powders, and ultrafine powders, all meeting multiple standards such as Chinese GB, European FEPA, and Japanese JIS standards. Our products are exported to the United States, Japan, Taiwan, and other countries and regions.

In addition, Hongshun can customize and produce various specifications of silicon metal, high carbon silicon, silicon slag, and other alloy products according to user requirements. We welcome inquiries about our products or factory visits.