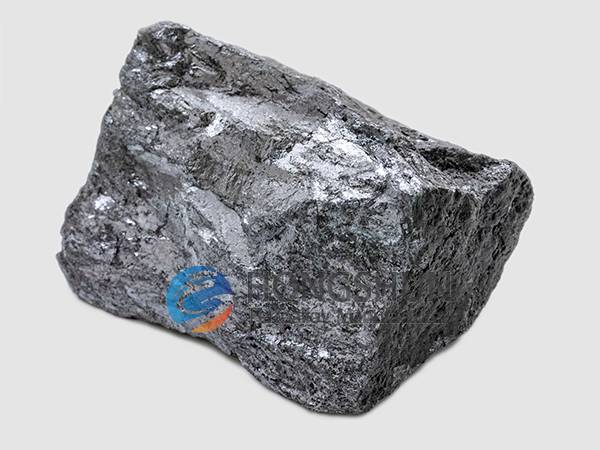

Calcium silicon, also known as calcium silicon alloy or ferro silicon calcium, is a composite ferroalloy primarily composed of silicon and calcium. As a ferroalloy, it contains various impurities including iron, aluminum, carbon, sulfur, and phosphorus in different amounts. Calcium silicon is available in the form of lumps or powders, widely used in steelmaking and other metallurgical processes.

Calcium silicon composition

| Model | Chemical composition (%) | |||||

| Si | Ca | C | AI | P | S | |

| ≥(min) | ≤(max) | |||||

| Ca28Si50 | 50 | 28 | 1.0 | 1.4 | 0.04 | 0.05 |

| Ca30Si50 | 50 | 30 | 1.0 | 1.4 | 0.04 | 0.05 |

| Ca28Si55 | 55 | 28 | 1.0 | 1.4 | 0.04 | 0.05 |

| Ca30Si55 | 55 | 30 | 1.0 | 1.4 | 0.04 | 0.05 |

| Ca30Si60 | 60 | 30 | 1.0 | 1.4 | 0.04 | 0.05 |

Application of Calcium Silicon

Calcium and silicon both have a strong affinity for oxygen, with calcium metal exhibiting an especially strong affinity not only for oxygen but also for sulfur and nitrogen. Therefore, calcium silicon is an ideal composite deoxidizer and desulfurizer in metallurgical processes.

The silicon component offers powerful deoxidizing ability, promoting the easy flotation and removal of impurities, while enhancing the plasticity, impact toughness, fluidity, and ductility of steel. Nowadays, calcium silicon alloy is increasingly used as a replacement for aluminum in final deoxidation.

Typical applications include:

Used in the production of various grades of steel and special alloys.

Acts as an inoculant and additive in the cast iron industry, improving graphite formation and mechanical properties.

Serves as a compound deoxidizer and desulfurizer to improve steel quality.

Functions as a heating agent in converter steelmaking workshops.

Used specifically as an inoculant for cast iron and as an additive in ductile iron production.

Production of Ferro Silicon Calcium

Ferro Silicon Calcium is typically produced by smelting a mixture of quartz (silica), calcium carbonate (limestone), coke, and iron scrap in an electric arc furnace at high temperatures. During the smelting process, calcium and silicon combine to form the alloy while impurities are reduced. The resulting ferro silicon calcium is then cooled, crushed, and screened into lump or powder form according to customer specifications.

Key raw materials include:

Quartz (SiO₂)

Calcium carbonate (CaCO₃)

Coke or charcoal

Iron scrap

Advanced production technology ensures a consistent chemical composition and high purity of the final product.

Advantages of Ferro Silicon Calcium

1. Excellent Deoxidizing and Desulfurizing Ability: Combines the strong oxygen affinity of calcium with silicon’s deoxidation power to efficiently remove oxygen, sulfur, and nitrogen impurities in steelmaking.

2. Improves Steel Quality: Enhances mechanical properties such as plasticity, toughness, ductility, and fluidity in various steel grades.

3. Versatile Form: Available in lump and powder forms, adaptable to different metallurgical processes.

4. Cost-Effective Alternative: Can replace aluminum in final deoxidation, reducing production costs without sacrificing quality.

5. Stable Chemical Composition: Produced under strict quality control, ensuring uniformity and reliable performance.