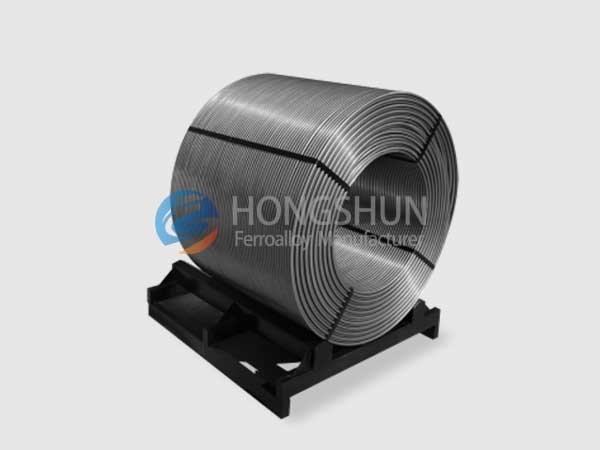

Carbon cored wire is a type of alloy cored wire widely used in the steelmaking and casting industries as an effective carbon-increasing agent. It is manufactured by crushing high-purity carbon raiser into specific particle sizes and wrapping them in a steel strip. The standard wire diameter is 13mm ± 0.5mm, and the carbon purity ranges from 90% to 98%, with customized specifications available upon request. The thickness of the steel strip used is between 0.3mm and 0.6mm.

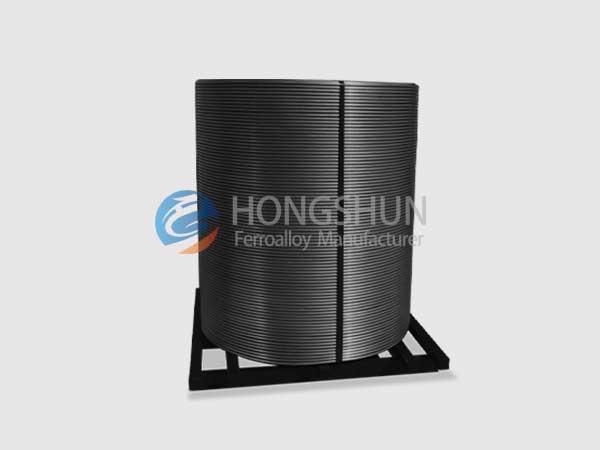

Produced using advanced core wire machines, the carbon cored wire features tightly packed filler with no spillage or leakage. The toner inside is evenly distributed and the product is securely packed in waterproof plastic and a steel frame to ensure stable quality during transport and storage. With a high carbon absorption rate of over 90% and a moisture content below 0.5%, this product ensures excellent performance in the furnace. Its high efficiency and stable composition make it a cost-effective solution for reducing production costs in modern steelmaking.

Chemical Composition of Carbon Cored Wire

| Type | Main composition % | Inside powder weight (g/m) | Steel strip thickness (mm) | Line weight (g/m) | Cored wire diameter (mm) |

| C | C>90 | 130±10 | 0.4±0.05 | 300±10 | 13±0.5 |

C Cored Wire Specification

Wire Injection Makes Steelmaking Easier

Using alloy cored wire in steelmaking offers significant advantages that simplify the refining process and improve overall efficiency:

Minimizes Impurities in Molten Steel: Some additives like calcium metal and carbon raiser have low melting points and light specific gravity. When added in lump form, they tend to float and form bubbles, reducing effectiveness. Alloy cored wire allows these materials to be injected directly into the bottom of the molten steel, avoiding such issues and ensuring better absorption.

Precise Control of Chemical Composition: The wire feeding system enables accurate control over the feeding speed and quantity of alloy addition. This precision allows for more consistent steel quality and helps meet strict compositional requirements.

Reduces Production Costs: The use of cored wire improves alloy yield, meaning less material is wasted. This efficiency leads to lower consumption of additives and ultimately reduces the cost of steel production.

Advantages of Carbon Cored Wire

High purity carbon (90%-98%) ensures efficient carbon addition with minimal impurities.

Tightly packed in steel strips to prevent powder leakage and maintain over 90% absorption.

Precise feeding control improves steel quality and composition consistency.

Reduces production costs by increasing alloy yield and minimizing material waste.

Why Choose HS Carbon Cored Wire?

High Quality: HongShun Carbon Cored Wire uses premium carbon materials with purity up to 98%, ensuring excellent performance in steelmaking.

Advanced Production: Manufactured with cutting-edge technology for tight packing and minimal powder loss.

Precise Control: Enables accurate and consistent carbon feeding for optimal steel composition.

Cost Efficiency: Improves alloy yield and reduces overall steelmaking costs.