Calcium Iron Cored Wire, also known as Calcium Iron Alloy Cored Wire, is a type of alloy cored wire made by mixing metallic calcium with a specified proportion of iron powder and wrapping it with a cold-rolled low-carbon steel strip. Typically, the core material consists of 28%–35% calcium particles and 65%–72% iron powder, enclosed within a low-carbon steel sheath.

With increasingly stringent requirements from major iron and steel manufacturers for low-carbon steel, ultra-low carbon steel, and low-silicon steel—particularly regarding inclusion content and form—calcium iron cored wire has become the preferred material for calcium treatment in the production of clean and pure steel.

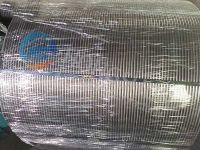

Calcium Iron Cored Wire Specifications

| Type | Main composition(%) | Inside powder weight(g/m) | Steel strip thickness(mm) | Cored wire diameter(mm) |

| CaFe | Ca:28-35 | 230-250 | 0.4±0.2 | 13-13.5 |

CaFe cored wire

Why Use Calcium Iron Cored Wire?

Calcium iron cored wire is designed to solve the limitations of traditional calcium-based deoxidizers in molten steel treatment. The advantages are as follows:

1. Overcomes rapid calcium evaporation

Although calcium is a strong deoxidizer, it has a low density and low melting point, making it prone to gasification and bubbling at high temperatures. Simply adding calcium particles or powder into the furnace often leads to instant combustion, preventing the material from reaching deeper levels of the molten steel and reducing its refining effectiveness.

2. Prevents molten steel splashing and protects equipment

Gasification of calcium in molten steel generates high vapor pressure, which can cause violent splashing, directly shortening the electrode life and accelerating furnace wear, posing safety hazards during smelting.

3. Optimized composition increases density and melting point

The core of calcium iron cored wire is made from a mixture of 28%–35% calcium particles and 65%–72% iron powder, wrapped in cold-rolled low-carbon steel strip.

The added iron powder helps to:

Increase the density, enabling the wire to sink quickly into the desired reaction zone.

Raise the melting point of calcium, thereby reducing evaporation losses.

Lower the production cost.

4. Accurate calcium delivery for effective reactions

By feeding calcium in the form of cored wire, it ensures precise release inside the molten steel, enabling more efficient deoxidation, desulfurization, and inclusion modification, which improves the purity and quality of the steel.

Advantages of Calcium Iron Cored Wire

1. Improves Steel Quality by Reducing Inclusions

Calcium iron cored wire acts as an effective deoxidizer in the steel refining process. Its addition helps prevent the formation of long strip-shaped sulfide inclusions, which improves the anisotropy and overall quality of steel.

2. Enables Deep Penetration and Efficient Reaction

With the assistance of a wire feeding machine, the cored wire is rapidly fed into the molten steel and melts at deeper layers, enabling thorough deoxidation, desulfurization, and removal of non-metallic inclusions.

3. Enhances Composition Control

Using calcium iron alloy cored wire allows for precise adjustment of alloy composition, improving the recovery rate of calcium and other rare earth elements, which ensures greater consistency and stability in steel composition.

4. Reduces Refining Costs

By increasing the efficiency of alloy element utilization, the cored wire helps reduce the amount of precious metals required during refining, which in turn lowers overall production costs.

Why Choose Hongshun Calcium Iron Cored Wire?

Hongshun is a professional manufacturer of alloy cored wires. We supply a wide range of products, including calcium silicon cored wire, pure calcium cored wire, calcium iron cored wire, carbon cored wire, and FeSiMg cored wire.

We prioritize product quality and support third-party inspections such as SGS, BV, and CCIC to ensure reliability and compliance.

Hongshun operates three production lines for alloy cored wire, with a total annual capacity of 30,000 tons, ensuring a timely and consistent supply to meet customer demand.