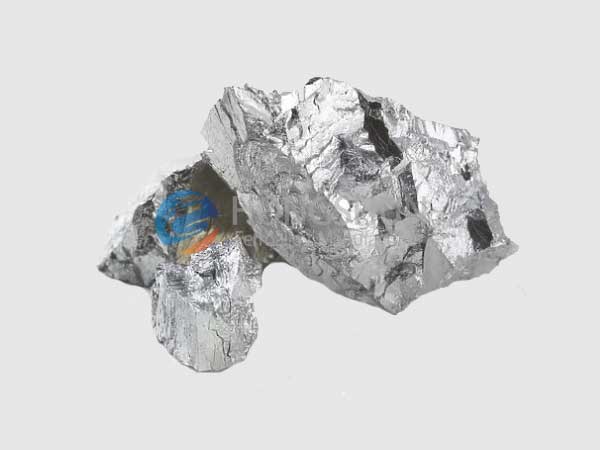

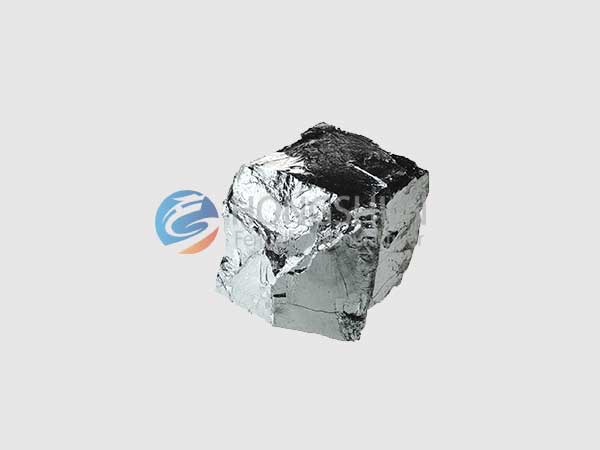

Chromium metal is a hard, lustrous, and corrosion-resistant transition metal widely used in various industrial applications. Known for its exceptional hardness, high melting point, and excellent resistance to oxidation and corrosion, chromium plays a vital role in alloy production and surface treatments.

Primarily utilized in the manufacture of stainless steel and other corrosion-resistant alloys, chromium enhances hardness, toughness, and wear resistance. It is also essential in the production of refractory materials, plating, and pigments.

Available in various forms such as chromium lumps, powder, and granules, chromium metal from reliable manufacturers ensures high purity and consistent quality to meet the stringent requirements of metallurgy, chemical, aerospace, and automotive industries.

Properties of Chromium Metal

1. Physical Properties:

Chromium is a hard, brittle metal with a silvery-gray metallic luster. It has a high melting point of 1907°C (3465°F) and a boiling point of 2672°C (4842°F). Chromium exhibits excellent hardness and is one of the hardest transition metals.

2. Chemical Properties:

Chromium is highly resistant to corrosion and oxidation due to the formation of a thin, stable oxide layer on its surface. It is chemically stable at room temperature and reacts with acids, alkalis, and oxidizing agents under specific conditions.

3. Mechanical Properties:

Chromium adds hardness and toughness to alloys, improving wear resistance and durability.

4. Other Characteristics:

It has good thermal and electrical conductivity and is magnetic in its pure form.

Uses of Chromium Metal

1. Stainless Steel Production

Chromium is a critical alloying element in stainless steel, providing corrosion resistance and enhancing mechanical strength.

2. Alloy Manufacturing

It is used in various alloys including nichrome, chrome-cobalt, and superalloys to improve hardness, heat resistance, and corrosion resistance.

3. Plating and Coatings

Chromium plating is widely used for decorative purposes and to protect metals from corrosion and wear.

4. Refractory Materials

Chromium oxide and chromium metal are used in manufacturing refractory bricks and other heat-resistant materials.

5. Pigments and Dyes

Chromium compounds are used in producing pigments for paints, inks, and dyes.

Why Choose HS Chromium Metal?

High Purity: Chromium content ≥99%, low impurities.

Stable Supply: Reliable production capacity and fast delivery.

Various Forms: Available in lumps, powder, and customized sizes.

Strict QC: Full-process quality control with optional third-party testing.

Competitive Price: Direct factory pricing with no quality compromise.

Responsive Service: Quick replies and professional technical support.