Ferrosilicon (FeSi), also known as ferro silicon, is a ferroalloy composed of iron and silicon. It is produced by smelting coke, steel scrap, and quartz (or silica) in an electric arc furnace. As a critical material in the metallurgical industry, ferrosilicon is widely used in the steelmaking, foundry, and various industrial sectors due to its excellent deoxidizing and inoculating properties.

As a professional ferrosilicon manufacturer, Hongshun Industrial specializes in supplying high-purity 75% ferrosilicon, 72% ferrosilicon, and 70% ferrosilicon. Our products are known for stable quality, competitive ferrosilicon price, and prompt delivery.

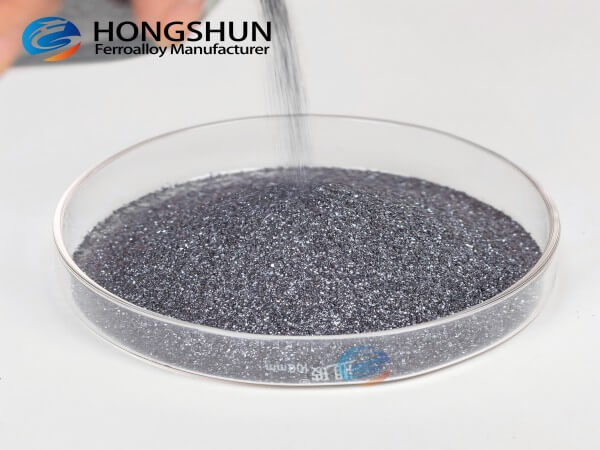

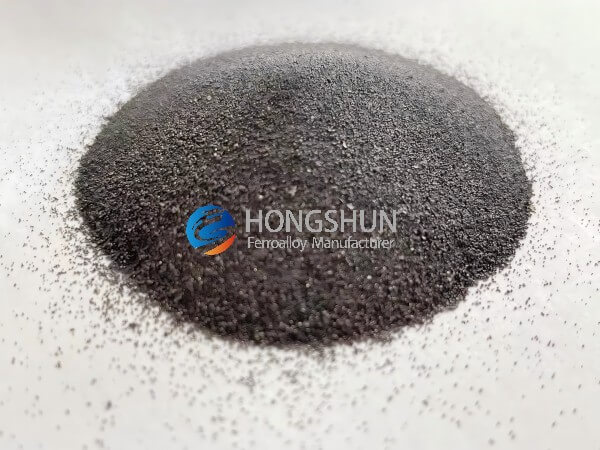

We offer various forms of ferrosilicon, including: ferrosilicon natural blocks, ferrosilicon lumps, ferrosilicon granules, and ferrosilicon powders. Available ferrosilicon particle sizes include: 0–1mm, 1–3mm, 3–10mm, 10–50mm, and 50–100mm, with custom sizes available upon request to meet your specific process requirements.

As one of the leading global suppliers of premium-grade ferrosilicon, Hongshun is committed to helping clients identify the best product for their application — whether in steel refining, cast iron production, or special alloy manufacturing.

Ferro silicon composition

| Normal Grade | Composition |

| FeSi75 | Si:75%Min C:0.2%Max Al:0.8-1.5Max P:0.03%Max S:0.03%Max |

| FeSi72 | Si:72%Min C:0.2%Max Al:2.0%Max P:0.03%Max S:0.03%Max |

| FeSi70 | Si:70%Min C:0.2%Max Al:2.0%Max P:0.03%Max S:0.03%Max |

| FeSi65 | Si:65%Min C:0.2%Max Al:2.0%Max P:0.04%Max S:0.03%Max |

| Low Al Grade 75%FeSi | Si:75% C:0.2% AL:0.2% P:0.035% S:0.02% |

Ferro silicon composition

Ferrosilicon Production

Ferrosilicon is produced by smelting silica (or quartz), coke, steel scrap, and iron filings in an electric arc furnace at high temperatures ranging from 1500°C to 1800°C. In this process, silicon is reduced from silica (SiO₂) using metallurgical coke as the primary reducing agent, and then dissolved into molten iron to form the alloy. Iron filings are typically added to regulate the iron content in the final product. For every ton of ferrosilicon produced, approximately 1780–1850 kg of silica, 890–930 kg of coke, 220–230 kg of iron filings, and 45–55 kg of electrode paste are consumed, along with a power requirement of 8400–9000 kWh.

Applications of Ferro Silicon:

1. Deoxidizer: Ferro silicon is widely used in the steelmaking industry as both a precipitation and diffusion deoxidizer, effectively removing oxygen from molten steel and improving its quality.

2. Reducing Agent: High-silicon ferro silicon or silicon-rich alloys serve as efficient reducing agents in the production of low-carbon ferroalloys within the ferroalloy industry.

3. Alloying Agent: Ferro silicon functions as an essential alloying element in the smelting of various steels, including low-alloy structural steel, composite steel, spring steel, bearing steel, heat-resistant steel, and electrical silicon steel. It is also used in the production of single crystal silicon and certain non-ferrous metal alloys.

4. Inoculant: When added to cast iron, ferro silicon acts as an inoculant for ductile iron. It helps prevent carbide formation, encourages the precipitation and spheroidization of graphite, and significantly enhances the mechanical properties of the cast iron.

5. Coating Material: Ferro silicon powder is utilized as a suspension medium in mineral processing and serves as a coating material in the manufacture of welding electrodes.

Ferro Silicon Market Shows Strong Demand Potential

1. Rising Demand from the Steel Industry

Hongshun observes that the steel industry remains the largest consumer of ferro silicon. On average, approximately 5 kg of ferro silicon is required for every ton of crude steel produced. While ferro silicon accounts for only about 1% of the total steel production cost, global steel output continues to rise steadily. As a result, demand for ferro silicon products such as ferro silicon lumps and ferrosilicon powder is also increasing year by year.

2. Magnesium Smelting Drives Further Growth

Ferro silicon is also a key reducing agent in the production of metallic magnesium, with each ton of magnesium requiring around 1.3 tons of ferro silicon. In fact, ferro silicon makes up nearly 50% of the total production cost for magnesium smelting. As magnesium increasingly replaces aluminum alloys in automotive manufacturing, particularly for lightweight components, global magnesium output is entering a phase of rapid growth—further driving demand for high-quality ferro silicon.

3. Hongshun — A Leading Chinese Ferro Silicon Exporter

As one of the top ferro silicon suppliers in China, Hongshun exports ferro silicon lumps and powders to markets worldwide, including Japan, the United States, South Korea, Belgium, India, Italy, Taiwan, and more. With reliable quality, stable supply, and competitive ferrosilicon prices, Hongshun is committed to meeting the evolving needs of customers across the steelmaking, foundry and magnesium industries.