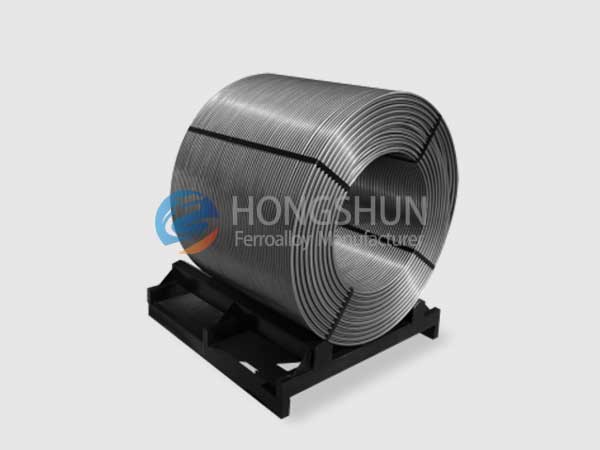

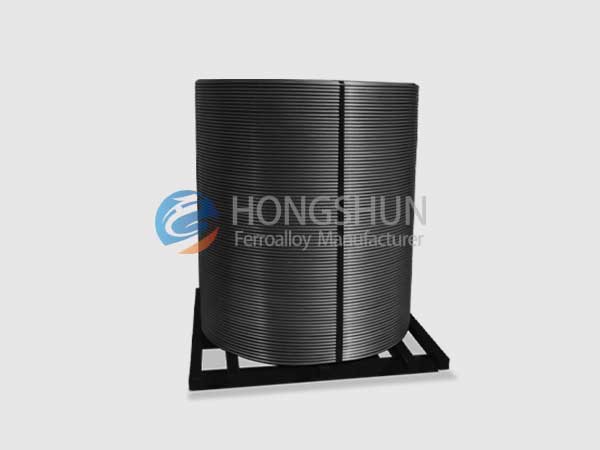

Cored Wire, also known as Alloy Cored Wire, is manufactured by crushing various additives—such as deoxidizers, desulfurizers, modifiers, and alloying agents—into specified particle sizes. These materials are then tightly wrapped in cold-rolled low-carbon steel strips to form continuous composite wires of various diameters. The finished wires are typically packaged horizontally in steel cages for easy handling and transportation.

Hongshun’s best-selling alloy cored wire products include Pure Calcium Cored Wire, Calcium Silicate Cored Wire, and Iron-Calcium Cored Wire, all of which are available in customizable specifications to meet different application needs in steelmaking and casting.

Chemical composition of cored wire

| Grade | Composition | Wire diameter(mm) | Steel belt thickness(mm) | Powder weight(g/m) | Uniformity |

| % | mm | mm | g/m | % | |

| CaSi | Si55 Ca28 | 13 | 0.4 | 230 | 2.5-5 |

| C | C98S<0.5 | 13 | 0.35 | 150 | 2.5-5 |

| FeTi | Ti25-40 | 13 | 0.4 | 510 | 2.5-5 |

| CaSiBa | Si55Ca15Ba15 | 13 | 0.4 | 215 | 2.5-5 |

| CaFe | Ca28-35 | 13 | 0.4 | 230-250 | 2.5-5 |

| BaSiAl | Si35-40Al2-16Ba9-15 | 13 | 0.4 | 215 | 2.5 |

| CaSiBaAl | Si30-45 Ca9-14 /B6-12 Al12-18 | 13 | 0.4 | 225 | 2.5-5 |

chemical composition of cored wire

Alloy Cored Wire Production Process

1. Raw Material Preparation

Cold-rolled low-carbon steel strips (9–16mm wide, 0.2–1.0mm thick) are used as the outer layer. The inner core materials—such as calcium, silicon-calcium, or carbon powder—are crushed to the required particle size.

2. Material Mixing

The powdered alloy materials are mixed evenly according to specified ratios.

3. Forming

The steel strip and mixed powders are fed into the cored wire machine, where they are crimped and sealed into wire form.

4. Coiling

The finished wire is wound into coils for packaging and shipment.

Use of Alloy Cored Wire

1. Meeting High-End Steelmaking Demands

With the continuous advancement of the steel industry, the demand for high-quality alloy steel and special steel has increased significantly, promoting the widespread application of cored wire technology.

2. Supporting Continuous Casting and Refining Improvements

The rising ratio of continuous casting and the steady improvement of ladle refining techniques have provided strong support for the development of cored wire application.

3. Enhancing Feeding Efficiency and Precision

Compared to powder injection or direct alloy block addition, feeding Hongshun cored wire into molten steel using wire feeding machines allows for more precise control of alloy addition and reaction timing.

4. Reducing Alloy Loss and Purifying Steel

This method effectively reduces alloy loss, improves alloy yield, and helps remove impurities, leading to cleaner molten steel.

5. Improving Product Quality and Reducing Costs

By ensuring stable reaction control, the overall performance of finished steel products is enhanced, and smelting costs are optimized, making Hongshun cored wire a preferred solution for modern steel mills.

Advantages of Hongshun Alloy Cored Wire

1. Stable Feeding and Low Breakage Rate

Hongshun alloy cored wire offers uniform powder feeding, consistent assembly dimensions, and a low wire breakage rate during the wire feeding process.

2. High-Quality Wrapping and Precise Weight Control

The wire is tightly wrapped and securely sealed, ensuring no powder leakage, gaps, false or empty packing. The surface is smooth, and the powder core’s weight deviation is generally controlled within ±5g/m.

3. Flexible Wire Types and Equipment Efficiency

Hongshun provides both internally drawn and externally released types of alloy cored wire. The required wire feeding equipment is simple, reliable, and space-saving—especially the internally drawn type, which is ideal for limited working spaces.

4. Improved Steel Purity and Inclusion Modification

The use of alloy cored wire purifies molten steel and modifies the nature and shape of non-metallic inclusions, thereby improving steel quality and casting conditions.

5. Efficient Alloy Element Control

Hongshun cored wire helps regulate and control easily oxidizable and trace elements, greatly enhances alloy recovery rate, lowers smelting costs, and allows for precise composition control.